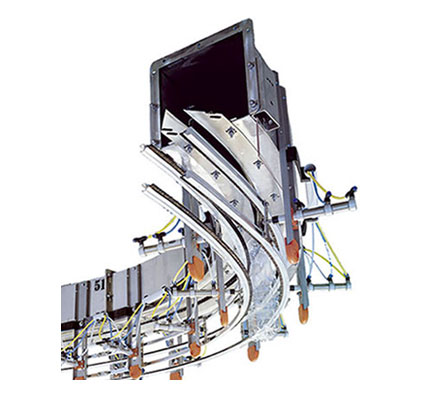

Conveyors - Air conveyors

Customized solutions for a quick and trouble-free transfer of empty PET containers of any shape and size from the blow molder to the filler.

Modular and ergonomic design

SMI air conveyors feature a modular design and a great operational flexibility, also thanks to the use of frequency converters (inverters) which optimize the conveyors speed. Furthermore, the stainless steel AISI 304 frame (1) makes the maintenance and cleaning operations easier. It is also possible to adjust the air distribution system according to the type of bottle, by means of manual valves or through the electronic control of the motors speed.

Low maintenance and operating costs

The product guides (2) are made of stainless steel and plastic UHMW antifriction material, whereas the guides controlling the bottles trajectory (3) consist of non-abrasive, plastic brushes (4), with the following advantages:

- they preserve the container quality

- they grant the correct side position of every kind of bottle

- they reduce the changeover times

- they reduce the wear levels and the maintenance operations

- they offer great advantages from the economical point of view (minimized operational costs)

Great flexibility for any kind of request

In order to ensure a high-quality air filtration, SMI offers a wide range of philtres (G4, G3, F9, H13, etc.) UNI-EN779. Furthermore, thanks to a user-friendly control panel, the operator can easily select the tracks position, according to the product format. SMI air conveyors can be wall-mounted or hung to the ceiling, with great advantages from a logistic point of view.

* The stated values are not binding, as they have to be confirmed by SMI according to the user’s production conditions.